VECOTRADE delivering solutions

Seventy years of experience in plant design

With more than seventy years of experience in the design of plants and machinery for the shredding, screening, conveying and storage of wood, paper, files, substitute fuels, plastics, household and commercial waste, as well as the design and realization of plants for sawmills, gluelam plants, particleboard plants, pellet plants, biomass plants, boiler plants, and sorting and processing plants in the recycling sector, our claim is always a satisfied customer. We achieve this with a well-coordinated team and flexible partners.

Our products

Size reduction technology

The heart of successful processing is comminution - for this reason, we work with you to develop the optimum comminution solution precisely tailored to your input materials.

Conveyor technology

Our conveyor solutions, which are individually tailored to your conditions, are adaptable in size, length and performance and enable you to ensure a continuously running material flow in your recycling and processing plant.

Screening technology

With the help of efficient material separation, we generate high quality and optimised added value for your processes. We integrate various screening solutions into the material flow and conveying process of your individual system.

Separation technology

Our separating machines and plants stand for the safety of your investment and guarantee a pure and homogeneous output with high quality.

Storage technology

Using the most modern and economical storage technology, we create the conditions for you for optimum material handling with given energy efficiency, economy and high availability.

Dosing technology

Our product and system plants enable you to optimally match your requirements by means of vibration technology, screw or push rod discharge.

Used machinery trade

We make it easier for you to enter new fields of business cost-effectively by means of a selection of used machines.

Roundwood handling

With the help of our log conveyors, we offer you short and long log transport as well as log feeding in sawmills. We also supply the entire sorting process.

Sawn timber handling

Our sawn timber conveyors handle the transport, sorting and stacking of sawn timber for you.

Glulam handling

Furthermore, we offer you the complete mechanisation for glulam plants and plants for the further processing of wood.

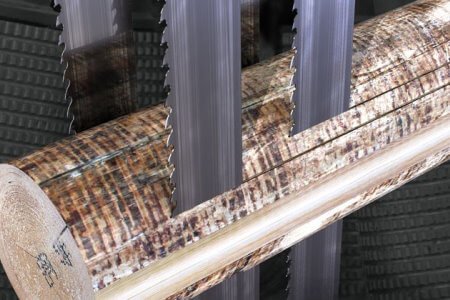

Log band saw technology

Using the latest log band saw technology, we offer you more flexibility, higher added value and production reliability. You benefit from the fast and gentle cutting process with a high degree of automation and universal sawmill use.

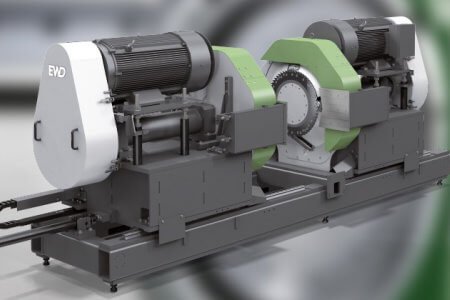

Reducing band saw technology

The modular design of the EWD bandsaw technology ensures flexibility, high yield and performance and any task in the modern sawing industry can be solved.

Edging technology

Our Combimes trimming and re-trimming system is characterised by reliable performance, a wide range of configurations and high added value in the performance class. It can be used for various production tasks.

Circular Saw & Profile Technology

Our products include the PF 19 profile chipper, as well as the DWK and VNK pre- and

post-cutting circular saws, and enable maximum results in cutting wood.

Creel technology

With the help of our fast and efficient oscillating frame creel, we achieve the best surface qualities and high feed rates.

Material flow solutions

In addition to planning customer-oriented conveyor technology for new systems, we also support you with intelligent material flow solutions for the expansion, modernisation and further development of your current system.

Spare parts service

We supply spare and wear parts for all Vecoplan, M-TEC and EWD machines. Our experience guarantees you the optimum wear parts for your needs. We also offer knives and counter-knives for machines from other manufacturers.

Maintenance & Service

As with our plants and machines, you can rely on our employees. They are at your disposal from the first contact, through the realization of your project, to the operation / after-sales of the plant with expertise and tips. We have well-trained and experienced fitters who carry out necessary repairs, maintenance, conversions and rebuilds at the customer's site, both at home and abroad.

CE Marking

CE Consulting

Special measurement in the industry